Privately-owned water tanks supplying fire protection systems have a long history. The NFPA published the Standard on Gravity Tanks in 1909. It is one of the oldest NFPA codes, predating even the Life Safety Code’s precursor, the Building Exits Code, first published in 1927. The Standard on Gravity Tanks evolved over the years to become NFPA 22, Standard for Water Tanks for Private Fire Protection. The inspection, testing, and maintenance requirements for all types of private fire water storage tanks are laid out in NFPA 25, Chapter 9 – Water Storage Tanks. While there are about eight different types of fire water tanks, I’d assert that the most common type today is the steel suction tank.

Though fire pump suction tanks can be rather ordinary-looking, there’s more going on than at first meets the eye. They are not something that should be forgotten in the scope of fire protection inspections, testing and maintenance (ITM). This blog is not intended to provide comprehensive coverage of the ITM needs of fire water tanks, but to highlight some issues that routinely turn up during inspections of steel suction tanks – especially inside them!

Left – the most common private fire water tank of yesteryear, and right, the most common fire water tank today: the steel suction tank

But first, a look outside

The most important thing to routinely verify is the water level in the tank. Fire water tanks must be maintained at their design water levels, or full if a design water level is not known. While there are lots of ways to measure a liquid level in a tank, for steel suction tanks, a simple float-type level gauge is often used.

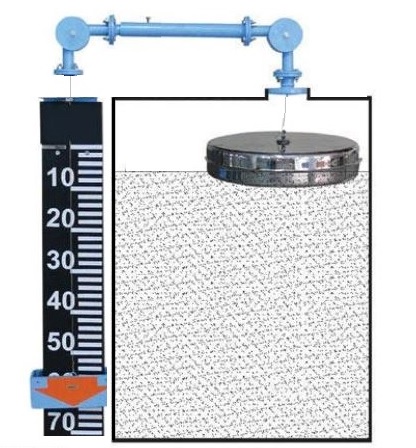

A representation of a float and board level indicator

The indicator of a float-type level gauge moves along cable guides, left* or, for a float & board type, along a metal ‘board’ with measurement graduations, right.

Two common issues that can occur with float-type level gauges are getting stuck or a cable breaking. I recall a time when a tug on a tank’s level indicator unstuck it and it took off! When the indicator re-settled, the tank that had appeared to be full was not even half! Not good! If there’s ever any doubt with the accuracy of a fire water tank’s level measurement, one way to be assured of the level is to fill the tank to the overflow spout.

Fish-eye view of a level gauge’s float, from a submersible looking up from below*

On the inside

A steel tank without corrosion protection should have an internal inspection every 3 years; with corrosion protection, every 5 years. Problems on the inside of a tank, such as pitting, corrosion, failure of coating, silting, or problems with the vortex plate, can develop and progress unseen but for these periodic internal inspections. Happily, there is no need to drain all the water out for an internal inspection; they can be done using submersibles or divers! These inspections can have some of the most fascinating work products: underwater photos and video. Submersibles or divers can be employed to vacuum out sediment as well. If you thought, meh, who cares if there’s a little dirt in the fire water? Consider: the discharge outlet of the tank, feeding the fire pump, will be fitted with an anti-vortex plate that will be as close as 6 inches to the bottom of the tank, to maximize the volume of water available to the fire pump. Then consider that sediment can accumulate to a few inches, depending on the water.

Sediment built up on the floor of a fire water tank*

Left – an anti-vortex plate* Right – a broken corner of an anti-vortex plate tank*

It’s not terribly unusual that an internal inspection reveals foreign objects in the tank. What is this? Your guess is as good as mine. *

When repairs or recoating are needed, the tank does usually have to be drained. For an internal inspection, a fire water tank can be maintained full, right where it should be.

I hope that you can appreciate that the suction tank has more going on than at first meets the eye. Fortunately, thorough visual inspections, inside and outside, can cover many common issues with one and help ensure that the fire protection water supply is ready to go if needed.

Amy Anderson, PE, CFEI, has a Bachelor of Science in Chemical Engineering from Clemson University and is a licensed Professional Engineer in Fire Protection, as well as a Certified Fire and Explosion Investigator. Amy has over 20 years of engineering experience including property loss prevention engineering specializing in fire protection, chemical and pharmaceutical facilities. She has partnered with clients to identify, assess, avoid, and reduce risk at their commercial and industrial properties. Additionally, she has assisted with the development of building and fire protection specifications, reviewed plans and performed site visits. She has reviewed project documents for compliance with applicable standards – construction, fire protection, process, and combustible dust hazards. Amy is a member of the National Association of Fire Investigators, the Society of Fire Protection Engineers, the National Fire Protection Association and the American Institute of Chemical Engineers.

* Image courtesy of Preferred Tank and Tower